Office equipment, IT, telecom devices.

Technology development equipment

Industrial automation equipment

Components and accessories for electric vehicles

Measuring instruments

Home Appliances

6-axis force and torque sensing (Fx, Fy, Fz, Tx, Ty, Tz)

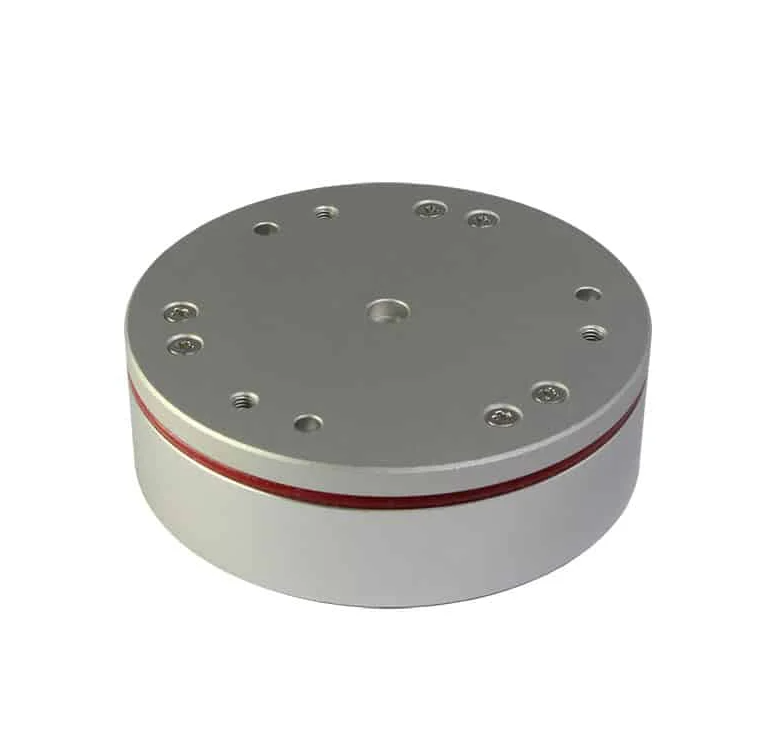

Compact form factor (Ø64 mm), suitable for small to medium robotic arms

High resolution for precise measurement of small forces and torques

High overload capacity up to 300% FS, resistant to impact and accidental collisions

Flexible communication interfaces: Ethernet / CAN / USB (configuration-dependent)

Designed for tactile manipulation, contact force evaluation, and collaborative robots (cobots)

Lightweight structure, minimizing impact on robot dynamics

Manufactured in South Korea, meeting industrial research and commercial standards

Free shipping radius TOÀN QUỐC

Free shipping radius TOÀN QUỐC

Contact support for detailed quote: Hotline: 0386365636 - Mr.Sơn

Buy at Vina Connect Showroom See directions

The RFT64-SB01 is a compact 6-axis force and torque sensor designed for robotic applications that require high-resolution force feedback and stable integration. With a diameter of 64 mm and a height of 30 mm, the sensor can be easily mounted on small to medium-sized robotic arms without affecting kinematics or payload performance.

The sensor supports simultaneous measurement of forces and torques along all six axes, making it ideal for demanding tasks such as robotic assembly, polishing, grinding, and force-controlled welding. Its high sensitivity, with resolutions down to 0.2 N for force and 0.01 Nm for torque, enables accurate detection of subtle contact changes during manipulation.

A key advantage of the RFT64-SB01 is its exceptional overload tolerance, capable of withstanding up to 300% of the full-scale load without damage. This feature provides strong protection during unintended collisions or minor operational errors.

With support for USB, CAN, and Ethernet communication, the sensor integrates seamlessly into various robotic controllers, PLC systems, and PC-based platforms. Developed by ROBOTOUS (South Korea), the RFT64-SB01 is widely used in industrial robots, collaborative robots, testing systems, and AI-based tactile learning applications.

Please visit our comparative table for a complete listing of features and specifications.

Note: If you desire an EtherCAT interface for this sensor, purchase the CAN version of the sensor and also buy the Robotous RFTEC-02 EtherCAT Adapter.

| Item | Specification |

|---|---|

| Model | RFT64-SB01 |

| Dimensions (Ø × H) | 64 mm × 30 mm |

| Weight | 175 g |

| Number of axes | 6 (Fx, Fy, Fz, Tx, Ty, Tz) |

| Rated capacity | 200 N (force) / 10 Nm (torque) |

| Resolution | 0.2 N / 0.01 Nm |

| Overload capacity | 300% of full scale |

| Output signal | Digital (USB / CAN / Ethernet options) |

| Power supply | 12–24 VDC |

| Operating temperature | −10 °C to +50 °C |

| Supported protocols | Open communication, SDK available (C++, Python, etc.) |

| Applications | Collaborative robots, polishing, welding, tactile AI training |

| Origin | South Korea – ROBOTOUS |

| Warranty | 12 months (depending on local distributor) |

A. Installation Preparation

Determine the mounting position on the robot wrist or test fixture.

Install the sensor using the specified threaded holes or mechanical adapters (M4/M6 depending on model).

Connect the sensor to the controller using the supplied signal cable (Ethernet, CAN, or USB).

Supply appropriate power (typically 12–24 VDC).

Ensure all mechanical connections are secure to prevent measurement errors.

B. Startup & Calibration

Power on the system and launch the provided control software or SDK.

Execute the Zero calibration to eliminate force and torque offsets caused by tool weight.

Optionally use calibration weights to verify linearity and accuracy if required.

C. Operation

Integrate the sensor into the robot control loop for real-time force feedback.

Use it to monitor pressing force, contact force, or interaction forces during assembly, polishing, or soft-object manipulation.

Transmit data to a PC or PLC for AI processing, behavioral analysis, or robotic training.

D. Storage & Maintenance

Prevent water, dust, or oil from entering signal connectors.

Avoid strong impacts or prolonged operation beyond rated load limits.

Periodically check mounting tightness.

Store in a dry, moisture-controlled environment when not in use.

We will contact and send a quote based on the information you provide!